For media or press inquiries, contact:

Age has chipped away at the inside of this forgotten warehouse on the former Navy base, where the industrial scaffolding that stretches to the ceiling is appropriately colored orange.

Three years from now, Clemson University scientists will use this rundown space to help wind-turbine manufacturers test their drive trains, which harvest the energy from the rotation of a turbine’s blades.

State leaders and economic development officials hope the testing ground will become the center of an alternative energy hub, a source of thousands of jobs and a springboard for economic growth.

The $98 million project will bring together major wind- turbine-company executives from around the world Friday. They will convene in North Charleston to serve on two advisory panels that aim to guide the research facility’s progress.

“It’s the beginning of working with industry leadership … because this is about building a business model and building a business,” said Elizabeth Colbert-Busch, director of business development at the Clemson University Restoration Institute.

The group has the extraordinary task of designing a test facility that can handle mega-drive trains, which are so large they won’t fit at any existing test center.

Wind turbines typically can handle between 3 and 5 megawatts of power. The Clemson facility will be designed to handle turbine parts that can process up to 15 megawatts, enough electricity to power 20,000 homes.

The advisory panel’s work will start with developing a plan to renovate the former storage warehouse, which is littered with abandoned paper files and pallets of plastic-wrapped office supplies.

In dimly lit corners there are clusters of computer parts so lumbering and outdated that they were built on a wheeled frame, technological relics from the green-screen era.

Spindly shrubs have woven their branches in and out of a screened openings at the building’s base. Floor tiles have eroded away in small blocks of offices scattered throughout the warehouse.

The State Ports Authority donated the 82,000-square-foot warehouse to Clemson’s effort. The state Commerce Department and the S.C. Research Authority also contributed money to help match a $45 million grant for the turbine facility.

Another big challenge facing the advisory panels will be to design a facility that can accommodate the massive size and weight of drive trains.

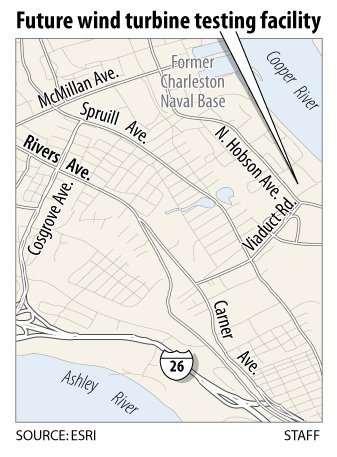

The facility, which will employ about 20 workers year-round, will test units that can weigh up to 300 tons each. That’s heavier than a 787 Dreamliner jet filled with fuel, luggage and passengers. The size of the turbine parts makes it difficult to transport them, which is why local economic development officials are hopeful that manufacturers will want to build them nearby, possibly in some of the vacant, nearby warehouses scattered throughout the former Navy base.

[email protected] or call us at +1 843.767.9300